The commercial path

Commercial rotor control protection systems must use un-obtainium in their construction or are priced at what the market will bear.

I tend think the latter after asking a few hams who went the commercial route to take a look inside at the components used. Nothing wrong with buying commercial, but a $170 protector for a $390 rotor system does not make sense. So I went about gathering up the parts to make my own.

Parts needed

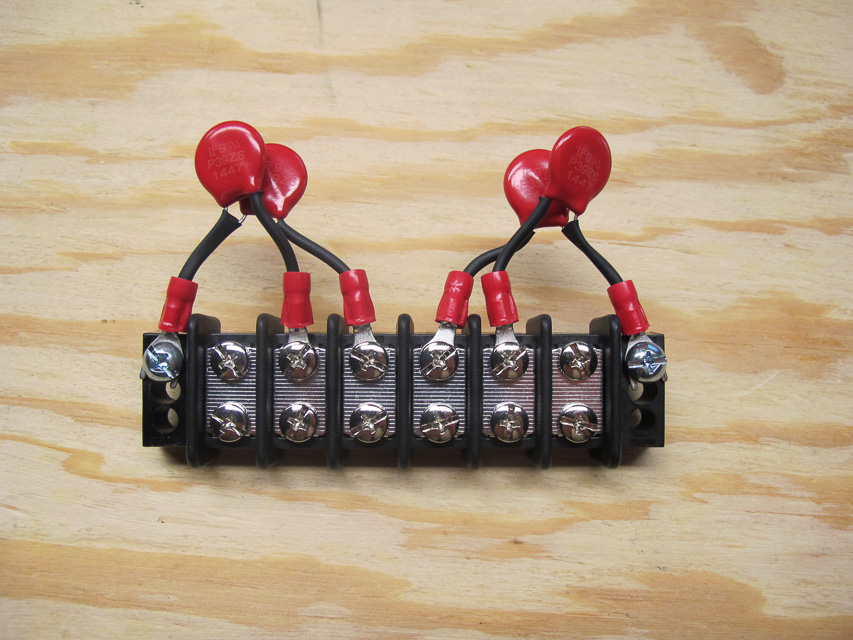

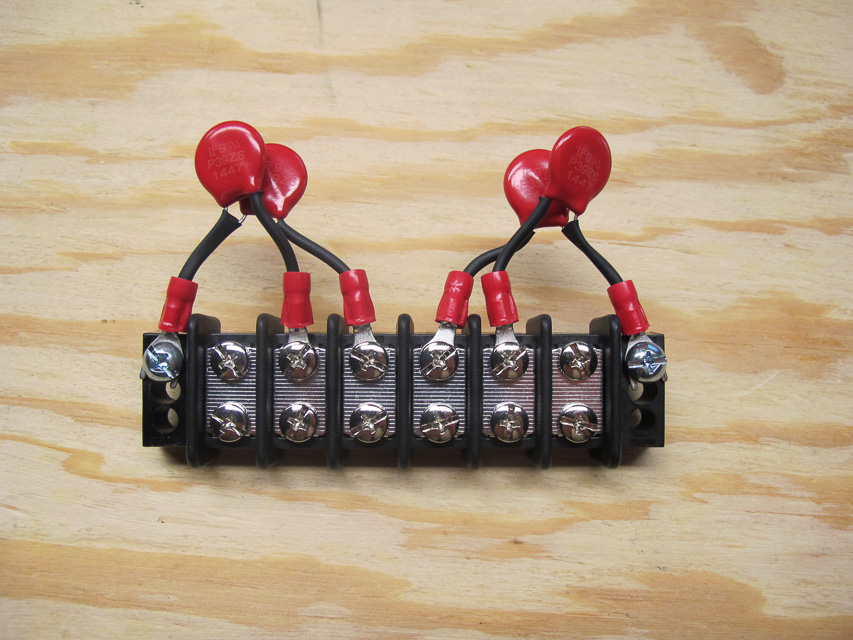

While the Yaesu G-800SA calls for a 6 wire control cable only 4 wires are actually used, so I selected an appropriate terminal strip and ordered a dozen or so Littlefuse brand MOV’s from Arrow Electronics.

Researching the normal operating potentials I selected a part rated at 25VAC/31VDC and using ring terminals and heat shrink tubing I assembled a suppressor for use at the tower base. The terminal is the highest single point item and I picked this up in the electrical dept of a local big box home improvement store. The MOV’s are 25c each and the tubing and connectors perhaps another buck. All in minus my time less than $5 total investment.

Installation

A simple matter then to fasten and ground the terminal strip in the suppression cabinet. Followed by striping and connectorizing the rotor cable and connecting it to the suppressor.

As MOV failure mode is very visual, they tend to explode when hit really hard, these are rated for 1000A. I should not have any difficulty determining when an event has occurred.

Until next time 73’s, Jay

Would there be any value to add gas tube protection in parallel with the MOV’s ? Is there any inherent incompatibility between the two technologies?

Good question, the two technologies are complimentary. The Littlefuse catalog discusses this point and the relative merits of both. The challenge is MOV’s which trigger at a much lower voltage and closer to normal operating voltage are available. The low end for gas tubes is 75v.

http://www.littelfuse.com/~/media/electronics/product_catalogs/littelfuse_gdt_catalog.pdf.pdf

73, Jay

Jay –

You used a MOV rated at 25VAC/31VDC for the Yaesu 800SA which has a rotor voltage of 20vAC.

What MOV rating would you suggest for the Yaesu g450a which has a rotor voltage of 24VAC?

73, rick

Rick,

I would consult the Little Fuse MOV product information site for their recommendation. If I recall I sized at a 20% headroom.

73, Jay

Hello!

Just wanted to thank you for the inspiration. I’m in the process of putting up a 55′ crank-down/tilt-over and was in need of lightning protection for my reconditioned Ham IV rotator. In a search, I came across your design and adapted it to a Euro type terminal board with 8 MOVs for the Ham IV control wires. It is mounted on a 2″ X 6″, .025″ thick piece of copper ground strap with the ground side of the MOVs soldered directly to the copper. I’ll mount it with 3M double-sided tape in my cable entrance box and it will be attached to the single point ground system with a .5″ braided ground strap fastened with 10mm stainless steel nuts and bolt on the copper strap. Could send a picture if you like.

Graham,

The station here took a direct strike a few weeks back which despite the protection took out the rotor and controller. Once I swap it out and am able to identify the failure mode I may revise my protection system. Yours sounds like a solid implementation hope it is never tested 😉

73, Jay

Hello Jay,

Thanks. I hope so too. We had a strike last year on one of our pine trees out front that took out two big-screen TVs, a wifi router and a network hard drive with just its EMP. No direct hit on the house (thanks goodness). The MOVs should prevent that sort of thing, but probably not a direct hit.

Graham

It is a crap shoot with an EMP a lot depends on the effect on the ground and the line. As both are exposed to the magnetic field they may be at the same potential relative to other systems. Without relative voltage, little risk of damage.

Hi Graham W5AAG,

I’m at the stage of putting up a Rohn 25G at 40′. I also have my old Ham IV, vintage 1980, I’ve rebuilt and want to put it back up on the tower. I’m interested in your design and build of the rotor control line protection. I don’t know if you monitor this web site and don’t find your email on QRZ, so I’m giving this communication method a try.

Thank you,

Tom Norris NB5Q

Tom,

Jay (W0JD) here, did you have a question.

Do you have the part number for the mov 25/31

Not on hand, check out the Little fuse catalog available online.

Would love to hear if you’ve revised this system based on the lightening strike.

Ron,

Sorry for the delay, still the same I have it disconnected at the moment as I was moving things around in the box. Still part of the defenses.

73, Jay